Our Sustainable Technology

At UKHI, we combine cutting-edge biopolymer innovation with deep industry expertise to help manufacturers transition smoothly from traditional plastics to biodegradable and compostable alternatives. Our blown film extrusion resins are trusted by packaging producers, retailers, and industrial users across India and beyond.

Blow Film Extrusion Biopolymer

Biodegradable & Compostable Film Extrusion Granules

UKHI manufactures high-performance biodegradable & compostable blown film extrusion granules designed for sustainable packaging applications. Our Milky White, Semi-Transparent, Transparent, Stretch/Cling, Shrink, and VCI film resins are engineered for smooth processing in standard extrusion lines, delivering strength, clarity, and sealability.

Perfect for carry bags, grocery bags, garbage liners, stretch film, cling film, shrink wrap, mulch films, and food packaging, these eco-friendly polymer granules support global circular economy goals while reducing plastic waste.

Our Product Range

Milky White Film Resin (EGBF – OP)

Ideal for carry bags, grocery bags, liner bags, pouches/covers and garbage bags where opacity and strength are essential.

Semi-Transparent Film Resin (EGBF – TP)

Perfect for pouches/covers, shoe covers, shower caps and gloves requiring a balance of visibility and durability.

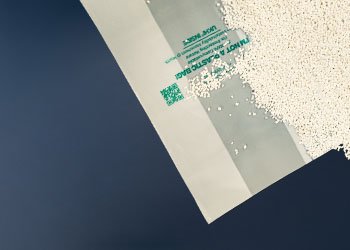

Transparent Film Resin (EGBF – TR1)

Delivers crystal-clear, compostable packaging films for food, retail, and consumer goods such as garment bags.

Stretch / Cling Film Resin (EGBF – SW)

High elasticity and tack, ideal for biodegradable stretch wrap and cling films for food or industrial use.

Shrink Film Resin (EGBF – SH)

Strong seal strength for biodegradable transparent shrink wraps and semi transparent shrink wraps in packaging and retail display applications.

VCI Film Resin (EGBF – VCI)

Protects metal goods from corrosion while being fully compostable.

High Shelf-Life Film Resin (EGBF – ML)

Designed for food packaging films that require extended freshness retention such as mulch films and nursery bags

High Barrier Film Resin (EGBF – BR)

Perfect for food packaging such as bread packaging bags and milk pouches.

Why Choose UKHI’s Biodegradable Blown Film Resins?

100%

Compostable & Non-toxic

Superior

Processability

Multiple

Film Grades

Cost-Effective

& Scalable

Made in India

Product

Universal

Equipment Compatibility

Designed to minimise capital investment for production line conversion.

Primary Applications

Technical Benefits

- High Tensile Strength for durability during use

- Excellent Clarity for visual appeal in retail packaging

- Strong Sealability for leak-proof packaging

- Customisable to meet specific extrusion line requirements

| Bag Type | Thickness / GSM | Approx. ₹/kg (India) | Approx. ₹/piece (16×20 size) |

|---|---|---|---|

| Conventional Plastic Bag | ~120 µm | ₹90/kg | ₹5.00–₹5.10 |

| Non-Woven Bag | ~60–80 GSM | ₹75–₹110/kg | ₹4.50–₹5.00 |

| Paper (Kraft) Bag | ~60–100 GSM | ₹60–₹90/kg | ₹7.00–₹11.00 |

Trusted by Industry Leaders

Made in India,

Made for the Planet

Strategic Partnerships

Testimonials

This product has truly simplified our work — smooth, reliable and efficient.

One of the best investments we made, highly recommended for every business.

Seamless experience from start to finish, we’re extremely satisfied.

FAQs

Yes, our biopolymers are designed to work seamlessly with standard profile extrusion machinery. Most manufacturers require minimal adjustments to temperature and screw speed settings. Our technical team provides detailed processing guidelines for smooth integration.

EcoGran™ reaches full compostability within 90–180 days, converting into soil nutrients without leaving any microplastic residue.

EcoGran™ matches or exceeds petroleum film performance with superior clarity, tear strength, puncture resistance, and barrier properties. All while being compostable.

No. EcoGran™ biodegrades cleanly, with no harmful or microplastic residues, only safe organic matter.

Absolutely. EcoGran™ film delivers excellent printability and gloss, enabling vibrant, high-quality packaging graphics.

Not necessarily. EcoGran™ runs on existing equipment without additional capital expense and offers competitive pricing comparable to conventional film resins with added environmental benefits.

UKHI provides full-scale support, from machine setup and speed optimisation to troubleshooting and process fine-tuning, to ensure smooth production rollouts.

EcoGran™ is ideal for a wide range of flexible packaging formats, including e-commerce mailers, product films, food storage bags, agricultural mulch films, shipping pouches, and industrial wraps.

Still have questions?

Contact our technical support team at info@ukhi.org or +91 9289970913 for personalized assistance with your specific application requirements.

Get a Quote

Fill out the form below for a personalized quote

Custom

Pricing for

Your Needs.

Send us your project Details for a bespoke Quote that fits your budget.