Before I talk of bioplastics, a word on plastics.

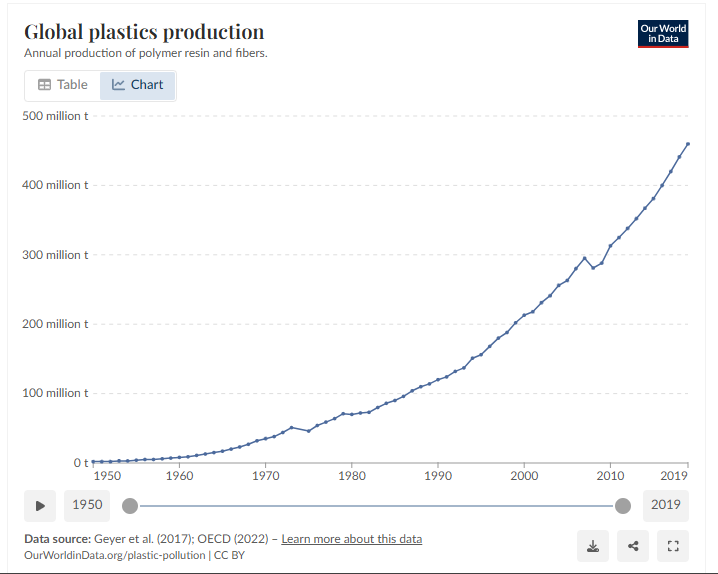

Every year we produce 450 million tons.

This number was just 2 million tons, in the 1950s.

Plastic became popular because it is cheap, convenient, and versatile.

But 43% of this plastic we produce is mismanaged at the end of its life. The plastic, instead of getting recycled, ends up in landfills and oceans.

So, what’s the solution?

That’s where bioplastics come in.

They function like regular plastics but are designed to degrade more quickly, reducing long-term environmental impact.

Still, for many people, the word “bioplastics” feels a bit mysterious. Are they really better? Are all of them biodegradable or compostable? And how exactly are they made?

In this article, I’ll try to answer these questions as simply and accurately as I can.

So what are bioplastics

At first glance, you might think “bioplastic” just means “plastic that biodegrades.” But it’s not quite that simple.

The term “bioplastic” is often confused with “biodegradable plastic,” even though they don’t always mean the same thing.

- Some bioplastics are made from plants but don’t break down any faster than regular plastic.

- Some plastics can biodegrade even though they are made from fossil fuels.

- And a few plastics check both boxes. They’re made from plants and break down easily.

Put simply, bioplastics are plastics that are either:

- Made from renewable biological sources like corn, sugarcane, or algae,

- Designed to biodegrade faster than conventional plastics,

- Or both.

Many people get confused by the phrase “bioplastics vs biodegradable plastics.”

To make things clearer, here’s a simple table that shows the main types:

| Type of Bioplastic | Source | End-of-life Behaviour | Example |

| Bio-based, non-biodegradable | Plants | Lasts like traditional plastic, does not break down easily | Bio-PET |

| Biodegradable, bio-based | Plants (corn, sugarcane) | Breaks down under the right industrial composting conditions | PLA |

| Biodegradable, fossil-based | Oil | Breaks down under proper composting conditions | PBAT |

This explains why the term “bioplastics vs biodegradable plastics” often gets confused.

How Are Bioplastics Made?

The bioplastic production process begins not in factories, but in fields and farms.

It is made of renewable resources like corn starch, sugarcane juice, or potato waste, depending on what’s locally available at the most affordable cost.

Here’s the step-by-step process of how bioplastics are made:

- Agricultural crops or residues are collected as feedstock

- Starches and sugars are extracted

- Microorganisms ferment the sugars into building blocks like lactic acid

- The building blocks are polymerized into materials such as PLA

- The resin is processed into products like films, bottles, and packaging

Let’s understand this with the example of PLA, the most common bioplastic.

It is made by fermenting corn starch into lactic acid and is then polymerized.

PHA (polyhydroxyalkanoates), however, is produced by bacteria, which store polymer inside their cells.

At UKHI, we use agricultural residues (like hemp and flax, for example) to make bioplastics. This reduces competition with food and helps agricultural communities get a new income stream.

What are the different types of bioplastics?

Not all bioplastics are the same. In fact, there are several categories based on their chemical makeup and use. Understanding these types helps us see where the biggest opportunities and limitations lie.

PLA (Polylactic Acid)

- Made from corn starch or sugarcane

- Transparent, rigid, often used in food packaging, cutlery, and 3D printing

- Compostable under industrial conditions

PHA (Polyhydroxyalkanoates)

- Produced by bacteria fed on sugars or oils

- Fully biodegradable in marine and soil environments

- Used in medical applications like sutures, as well as packaging

Bio-PET (Polyethylene Terephthalate)

- Chemically identical to PET but derived partly from plants

- Used in beverage bottles and textiles

- Not biodegradable but reduces fossil fuel use

Starch blends

- Mix of starch with other biodegradable polymers

- Flexible, used in bags and packaging films

This variety shows that there is no one-size-fits-all solution. Some bioplastics reduce fossil dependency, while others aim for full biodegradability. Irrespective of the specifics, bioplastics help reduce the negative impacts of traditional plastic.

Are bioplastics compostable?

In 2020, a University of Plymouth study tested “compostable” and “biodegradable” bags. The bags were left to compost in soil, water, and outdoor air. After 3 years, some of them remained intact enough to hold groceries.

So, if you are wondering, “Are bioplastics compostable?”, the answer is: Not always.

The compostability of a bioplastic depends heavily on the conditions in which it is left. Here’s when and how some bioplastics are compostable:

- Industrial composting: PLA and many starch-based bioplastics can break down fully. But it happens only at high temperatures (60°C) with controlled moisture and microbes.

- Home composting: Very few bioplastics compost effectively at home. Most will remain intact because the backyard pile cannot maintain industrial conditions.

- Landfill: Even compostable plastics often end up in landfills. There, oxygen and microbes are limited and breakdown is extremely slow, if at all possible.

At UKHI, we designed EcoGran™ to be compatible with existing manufacturing lines. This ensures more bioplastics can be composted without completely new composting infrastructure.

What are the environmental benefits of bioplastics

Bioplastics directly contribute to lowering global warming and saving the environment. The benefits of bioplastics can be seen in three main ways:

Lower Carbon Footprint

Traditional plastics are made from fossil fuels. Every additional ton produced adds to greenhouse gas emissions. Studies show PLA production reduces CO₂ emissions, resulting in a lower carbon footprint.

Reduced Fossil Dependency

Feedstocks (corn, sugarcane, and waste biomass) can replace crude oil to produce bioplastics. Bio-PET bottles, for example, already supply global brands like Coca-Cola with renewable options. This brings down dependence on traditional fossil fuels.

Biodegradability Potential

Some bioplastics, like PHAs, naturally break down in soil or seawater. This can help reduce plastic leakage into oceans, which is a major global concern. Other types of bioplastics can also be composted in special industrial conditions.

However, these benefits come with conditions. Large-scale cultivation of feedstocks may compete with food production and cause land-use conflicts. Also, compostability only works if infrastructure exists.

Further, while bioplastic production is scaling, it’s more expensive than traditional plastics. This makes it use and adoption limited.

Despite the challenges, the overall trajectory of bioplastics is positive. They align with circular economy goals and offer measurable reductions in emissions.

The road ahead for bioplastics

Global bioplastic production is growing fast. In 2022, it was only about 2.2 million tons. But it is projected to reach 7.4 million tons by 2028. This shows that the world is ready for low-carbon alternatives. Investors see real potential here. Real users are showing inclination.

But this growth also brings responsibility.

- For policymakers, it’s the responsibility to create better standards and composting infrastructure.

- For investors, it’s backing tech that scales without harming the planet.

- For educators, it’s helping people understand bioplastics and their use and disposal.

The road ahead will not be easy, but it is the right one. At UKHI, we are ready to take on the responsibility. Are you ready to join us?

FAQs

1. Are bioplastics better than traditional plastics?

Yes, but with conditions. Bioplastics cut carbon, reduce fossil fuel use, and compost, if the facilities exist. But without the right composting facilities, their benefits are limited.

2. What is bioplastic used for?

Bioplastics are used in a wide range of scenarios including:

- Packaging

- Cutlery

- Bottles

- Textiles

- Medical devices

- 3D printing

- And more

3. What are the side effects of bioplastics?

Some side effects include of bioplastics include:

- Higher production costs

- Limited composting infrastructure

- Competition with food crops

- Confusion over disposal

All these reduce its environmental benefits if mismanaged.

4. Is bioplastic water resistant?

Yes, most bioplastics are water resistant, but performance varies by type formulation.

5. Are bioplastics safe?

Yes, bioplastics are generally safe for humans, especially food-grade types. However, safety depends on additives, processing, and regulatory compliance.